Capacity range from 500 up to 10.000 m3/hr

Pumps

DE Klop pump lines

DE Klop can offer you two type of dredge pumps:

Rohr-Idreco iPump line

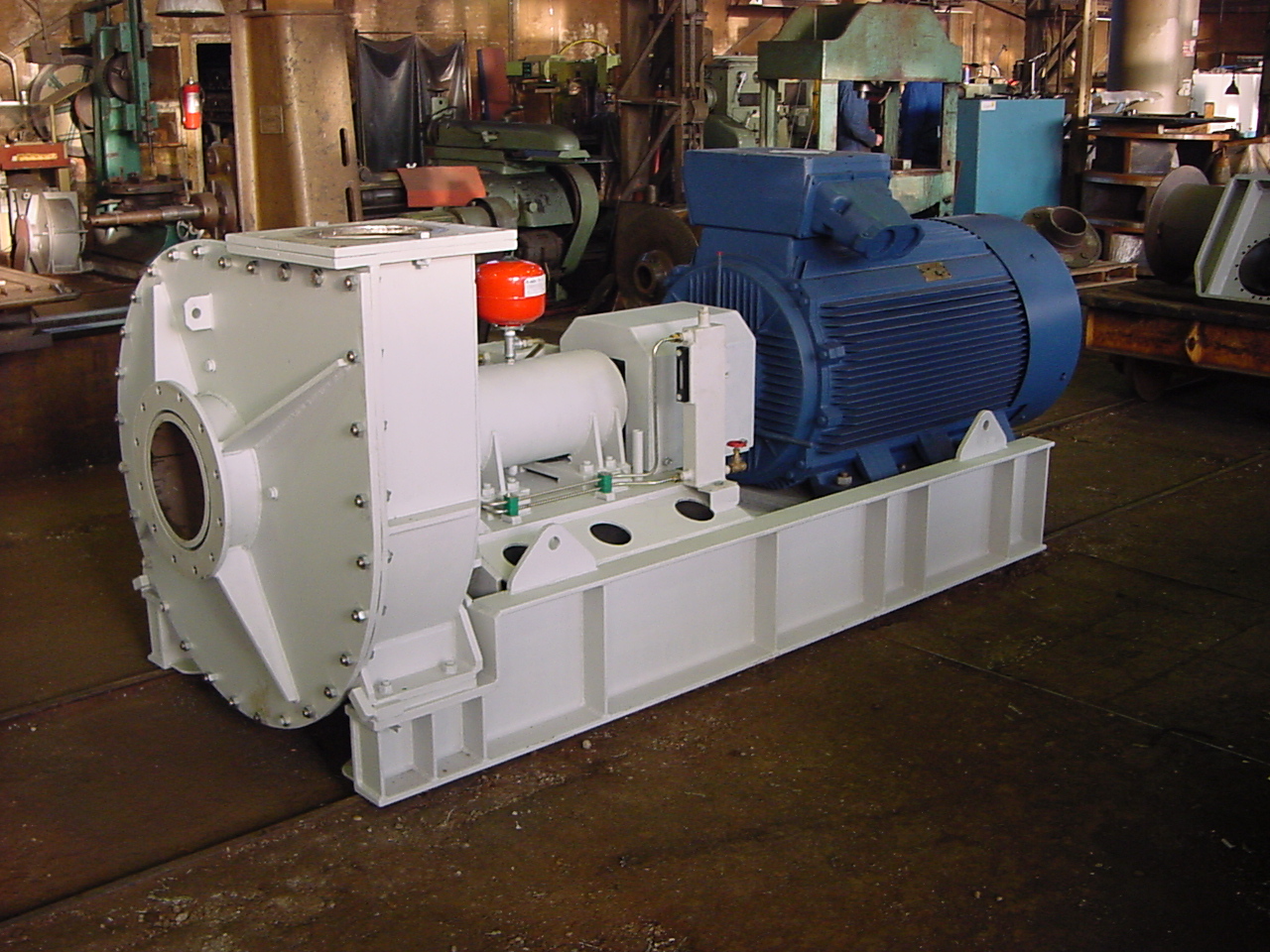

ROHR-IDRECO has proudly offered its comprehensive iPump® line for many years. Developed for the efficient transport of slurries containing abrasive loads from high percentages of fine particles, as well as mixed or impact loads from coarse grain material, our iPumps excel in demanding environments.

Increased Life Span

Leveraging the latest technologies, our iPumps boast enhanced wear resistance, optimal suction characteristics, and exceptional energy efficiency. These features result in high-performance operations, extended service life, and superior efficiency.

Versatile Applications

The iPumps are designed for a wide range of tasks. They can be integrated into ROHR-IDRECO dredging vessels, serving industries such as mining, dredging, and dam desilting. Additionally, they are suitable for applications in power and gas, special heavy construction, overburden storage/removal, slurry projects, and the transport of cuttings in tunnels and specialized civil engineering projects.

Key Benefits:

• High efficiency

• Long life of wearing parts

• High capacity

• Interchangeable wearing parts

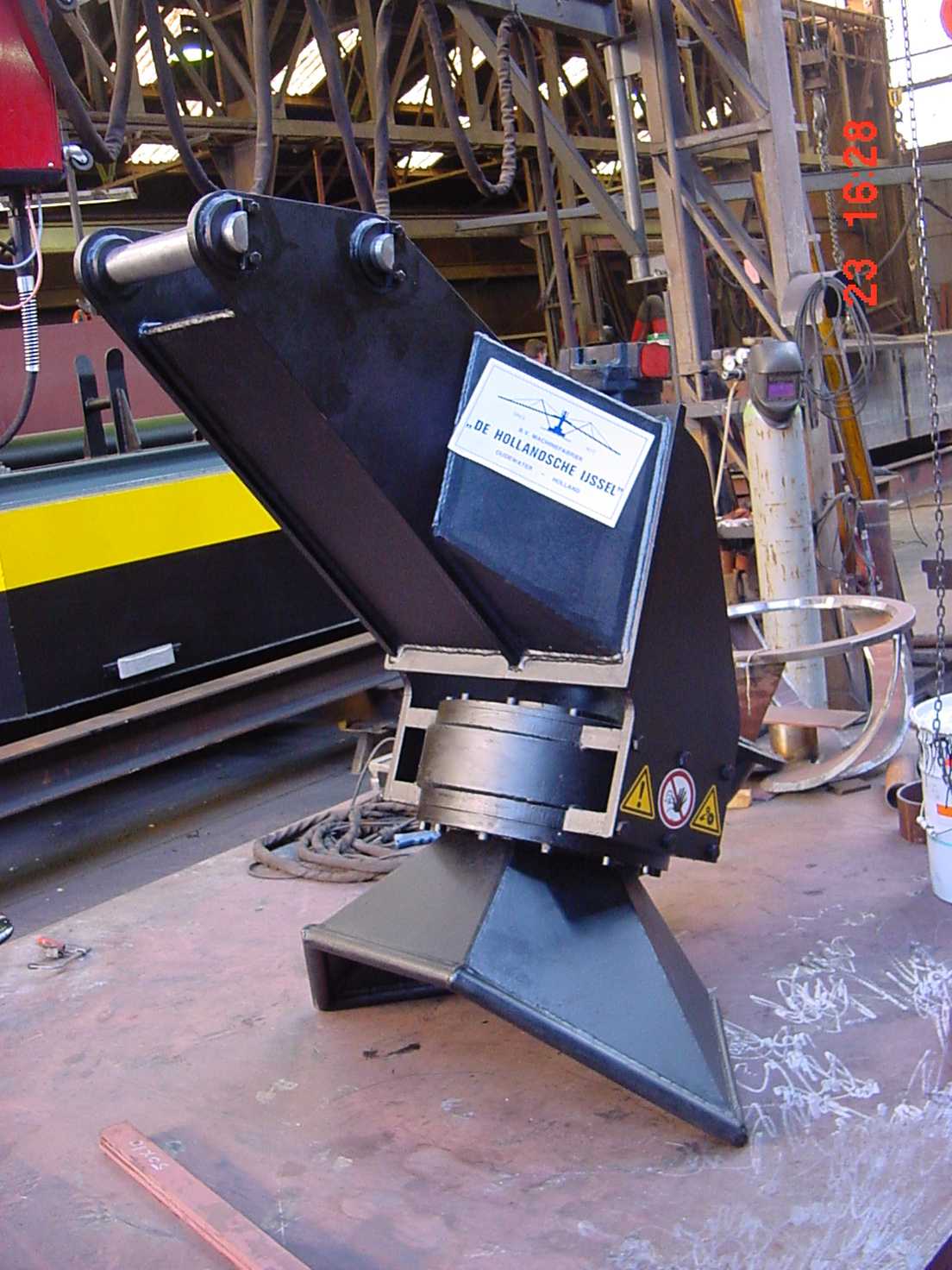

De Hollandsche IJssel Double Walled Dredge Pumps

Our double-walled dredge pumps are modern in design and crafted from top-quality wear-resistant materials. Components prone to wear are made from high-chrome alloy or excellent Nihard IV quality with a hardness of 550 HB. Manufactured with minimal tolerances, these parts are interchangeable. The impeller, threaded onto the pump shaft with a trapezoidal thread, can be easily dismounted using a three-part ring. The double-walled design ensures complete wear resistance while guaranteeing the safe use of the shell.

In comparison to single-walled pumps from competitors, our double-walled pumps provide enhanced safety for the vessel and its personnel in the event of a shell breakage.

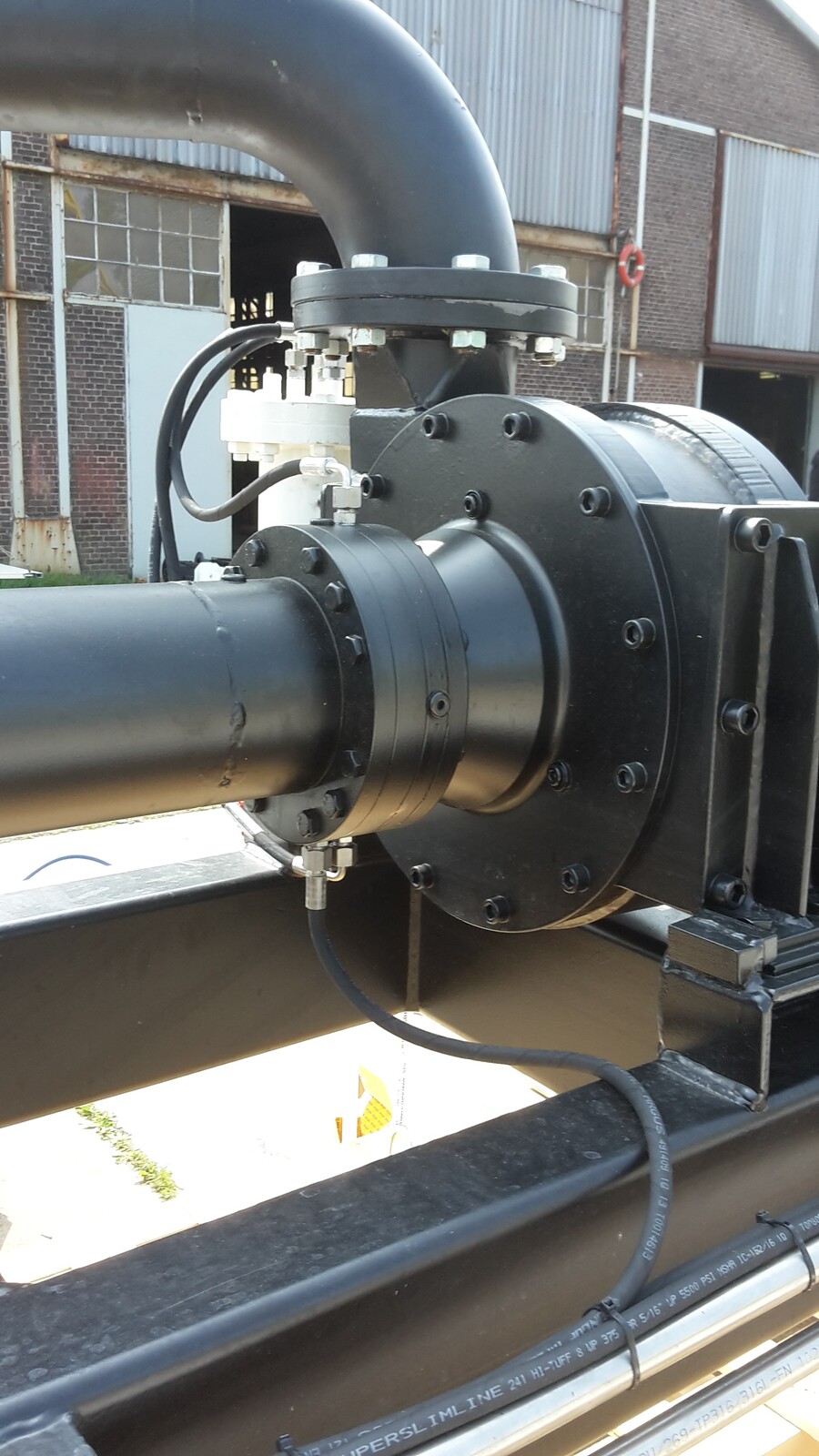

Shaft Sealing Arrangements

We offer various shaft sealing options. While the older system uses a stuffing box with flushing gland-water and grease lubrication, the modern mechanical seal is a popular choice. This leak-free mechanical seal, featuring Silica Carbide rings in a stainless steel housing, requires neither gland water nor grease lubrication, making it an environmentally friendly and maintenance-free solution.

For more information or advice, please click on the button below.

View our pumps

See our Pumps

Dutch quality

Quick response

Reliable

Sustainable

Value for money

More information

The double walled dredge pumps are used in

- Self Manoeuvring Cutter Suction Dredgers (SM CSD)

- Cutter Suction Dredgers (CSD)

- Trailing Suction Hopper Dredgers (TSHD)

- Special Cutter Suction Dredgers

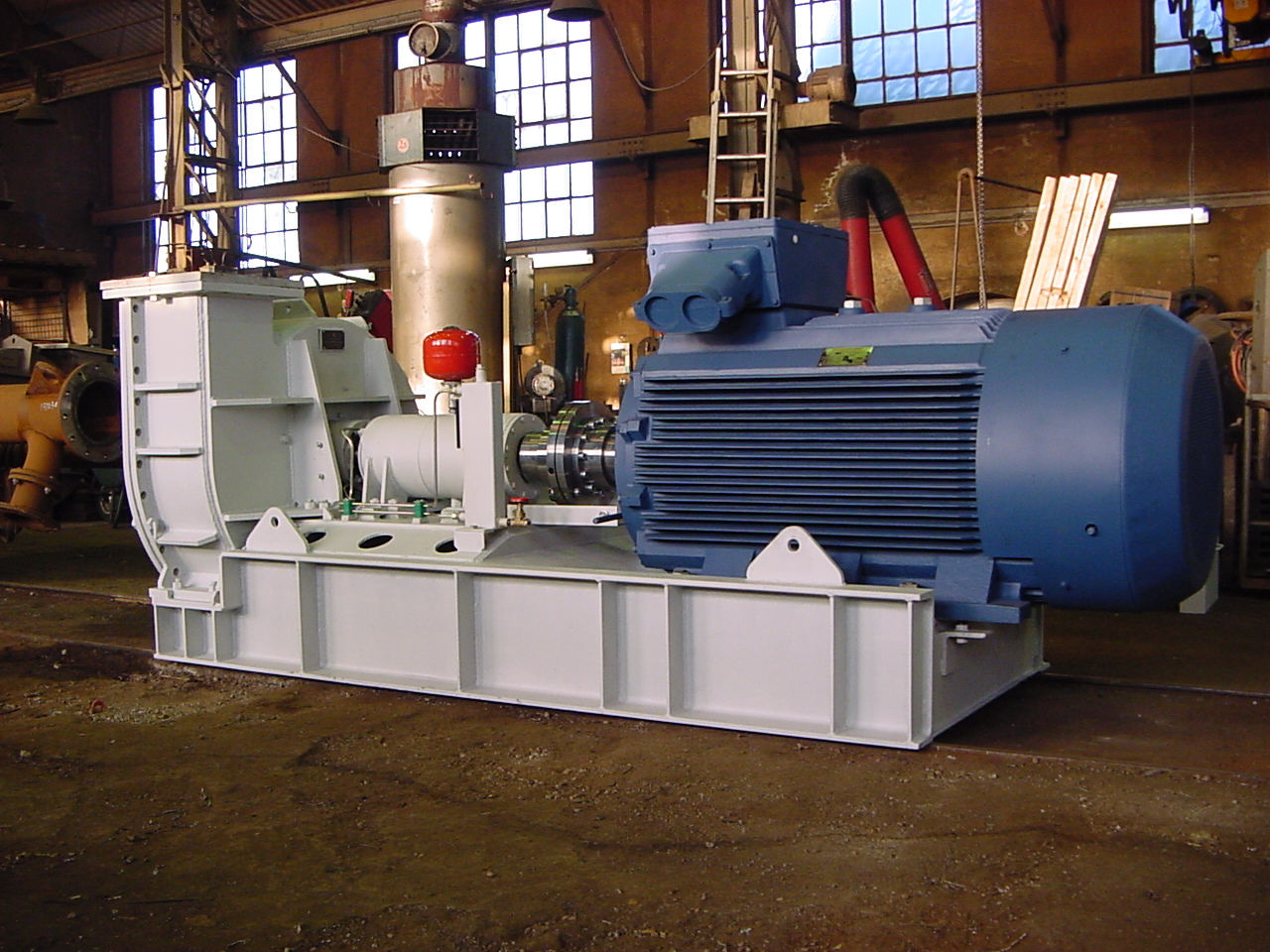

- Booster pump sets

De Hollandsche Yssel double walled dredge pumps are available for suction pipes 8” – 10” – 12” – 14” – 16” – 18” – 20” – 24” and 28”, so from 200mm up to 700mm.

The engineers of the company can assist in the selection of dredge pump type and size, diesel engine, gearbox, electric motor drive etc. Also production calculations for various types of soil on variable discharge distances can be made. For pumping distances over 2,000 – 3,000 meter, pipe line resistance and production calculations with one ore more booster stations can be made.