Master the Depths: Advanced Dredging Training

Training

Group Training Programs

DE Klop offers comprehensive training programs focused on the dredging-specific aspects of cutter dredgers. These interactive sessions combine theory with hands-on practice, providing participants with in-depth insights into the various conditions in which cutter suction dredgers operate.

On-Site Training Flexibility

The course can be conducted at the client’s office, offering a flexible approach that allows employees to participate without disrupting ongoing work. For those with more time, there is the opportunity to delve deeper into the theory and practice on the simulator.

Practical Experience

All participants have ample opportunity to practice on the mobile cutter simulator, developed by DE Klop in collaboration with MSA and Control Lab. The simulator provides realistic scenarios, enabling participants to see how their actions affect different conditions.

Training Highlights

Highlights of the training include a competition to achieve the highest production, with performances presented using the multiped. The multiped is a tool developed alongside the simulator to record and present performance and all parameters over time in an organized manner. Additionally, the tender competition in the final days, where participants in groups must submit a dredging project tender, is considered highly educational and challenging, allowing them to put theory into practice.

E-Learning Modules

In addition to these training programs, DE Klop offers E-learning modules about cutter suction dredgers (CSD). The E-learning courses are web-based, allowing students to complete them on their own computers in their own environments.

The CSD E-learning courses are available for different levels of experience and knowledge:

- Basic Course

- Advanced Course

- Professional Course

A test can be taken after studying the course material, and upon earning sufficient points, a certificate is awarded.

DE Klop’s training programs and E-learning modules are designed to equip participants with the skills and knowledge needed to excel in their roles, making them well-prepared for the challenges of operating cutter suction dredgers.

E-learning module

Course

Basic

The basic course covers dredging in general, the cutter suction dredger in particular, and contains the following subjects: Basic course

- Different types of dredging equipment and methods (trailing suction hopper dredger, cutter suction dredger, plain suction dredger, etc.).

- Types of cutter suction dredgers.

- Various components and parts of the CSD (such as cutter head, spud carriage, anchor booms, pump, pipeline, etc.).

Course

Advanced

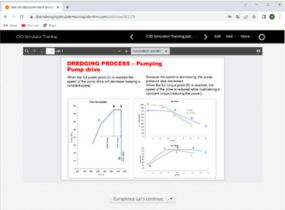

The advanced course covers the operation of the CSD and the relevant site conditions in respect to the dredging process:

- CSD operation; swinging, working on spuds (fixed spuds, spud carriage), positioning of anchors, cutting plan, discharge area.

- Soil types and the relevant properties for dredging.

- Sea state.

- The effect of the soil on the gathering process, cutting process, pumping process.

- The centrifugal pump; pump curves, pipeline characteristics.

Course

Professional

The professional course goes deeper into the dredging processes and focusses on optimization of the output of the CSD.

All the knowledge from the previous levels is applied to enable maximization of the production. Practical situations are explained with the theory. Finally a connection is made with readings of the instruments and control consoles of the CSD simulator, and actions to be taken to improve the production

Dutch quality

Quick response

Reliable

Sustainable

Value for money

On location

Hands-on CSD simulator training

Since the CSD simulator is a mobile set-up, training can also be provided at a location chosen by the customer with assistance of an experienced dredge master and/or trainer. The trainee is able to execise the operation of the CSD with different lay-outs of the controls (controls in desks, or controls integrated in joysticks), different soils, and assisted by a trainer and/or dredge master.

Training

Agenda example

Wondering what our training days are like? We have listed below for each day what you can approximately expect.