Shaping the future of dredging

About us

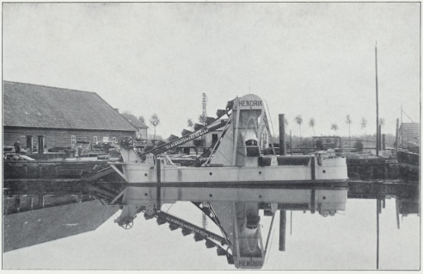

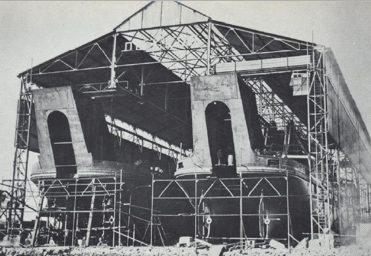

Around 1900, the Sliedrecht brothers Arie, Eliza and Jacob van Noordenne set up a repair shop in Zuilen to repair the equipment they used in their dredging and contracting work. After a number of years, the construction of new equipment also took place here, and a shipyard was created where the first ship was launched at the end of 1906. The shipyard was named after the nearby Fort De Klop.

The shipyard grew somewhat out of the hands of the brothers, and a more extensive basis was sought with a friendly relationship, which resulted in a conversion into a public limited company in 1911, with the participation of Gerrit-Jan Bos, contractor in Sliedrecht. The technical and practical management was in the hands of Huib(ert) van Seventer. In 1915 the decision was made to move the company to Sliedrecht: closer to the owners and the most important clients and because there were no expansion options in Zuilen. De Klop subsequently fell into the hands of W J Kalis Wzn & Co’s Baggermaatschappij, the Van Noordenne brothers and other parties withdrew.

The original founders and owners also wanted to continue to have their own workshop for their equipment, and so the Kraayeveld & Van Noordenne company, together with the Bos contractor family, decided to set up such an institution again in 1918, a few hundred meters further along the Merwede, below the name NV Shipyard and Machine Factory Kerkerak. In 1919, Kerkerak and De Klop were united into a company, under the leadership of the aforementioned Van Seventer, now with the original founders largely as shareholders and clients. In the first year the company had 214 employees. Over the years, Kerkerak’s equipment was transferred to De Klop, an operation that was completed in 1932.

The 1920s were quite profitable. In addition to dredging and tug boats, sea-going vessels were also built in the first years. The number of employees rose rapidly to 412 in 1921, after which a decline began. Like many shipyards, employment fluctuated widely, ranging from 370 in 1930 to around a hundred in 1933. In 1939, an adjacent site was acquired with a view to expansion. Which became effective in 1945. In the post-war period, De Klop also benefited from the flourishing of prosperity and Dutch shipbuilding, partly under the banner of the partnership with other Dutch Shipyards.

In 1965, five yards working together within IHC merged, including De Klop. De Klop survived the subsequent restructuring within the Dutch shipbuilding industry. In 1983, a new combined yard of De Klop and IHC subsidiary Van Rees was established and the combined company continued as IHC-Sliedrecht.

Around 2018 the shipbuilding activities were relocated from Sliedrecht and IHC IQIP was relocated to the IHC Sliedrecht Yard facilities. IQIP was sold in 2023 by Royal IHC. In the same year DE Klop BV was established in Sliedrecht by Cees-Wim van Noordenne, a descendant from the previously mentioned van Noordenne family. DE Klop BV has its offices almost at the same location as where it started in Sliedrecht more than 100 years ago.

Innovating Dredging Solutions Since 1872

The company philosophy

The company philosophy is to design and build dredging equipment mainly for inland dredging jobs and by this to fill a certain niche in the market. Supported by the know-how and experience gained from the operation of machines built for their local home market (The Netherlands) where private contractors execute inland dredging jobs for the Authorities, the company tries to be the best in the market.

Besides design and manufacturing in the factory in Sliedrecht, nowadays many jobs are engineered and drawings are made for local manufacturing. By supplying the key components and a set of installation drawings, this method can be effective for our clients and may save on labour and transport cost.

Dutch quality

Quick response

Reliable

Sustainable

Value for money

Get in touch with our experts

Arnold

den Boon

CEO & Electrical Engineer

adb@deklopbv.com

Marcel

Boor

Dredge Engineer

mb@deklopbv.com

Meindert Zwanenburg

Mechanical Engineer

mz@deklopbv.com

André

Kik

Naval Architect

ak@deklopbv.com

Rogier

Vollenbrock

All-rounder Dredge Equipment

rv@deklopbv.com

Cees-Wim

van Noordenne

Finance & legal

cw@deklopbv.com

De Klop B.V.